Ductile iron castings, like other metal castings, naturally develop internal stresses during solidification due to uneven cooling and phase transformation. Additional stress is introduced during machining from cutting forces and clamping.

If untreated, residual internal stress can release over time, causing dimensional changes, deformation, or even cracking—especially if the casting is constrained during use.

To ensure dimensional stability and structural integrity, stress relief treatment is essential before the casting is put into service.

Common Stress Relief Methods:

· Natural Ageing:

Long-term outdoor exposure to natural temperature changes; highly effective but slow. Ideal for precision parts like machine tool guideways.

· Vibration Ageing:

Controlled mechanical vibration accelerates stress release; suitable for faster industrial applications.

· Stress Relief Annealing:

Thermal treatment below phase change temperature with slow cooling; balances effectiveness and material preservation.

Each method is selected based on application needs, material properties, and required precision.

Each method is selected based on application needs, material properties, and required precision.

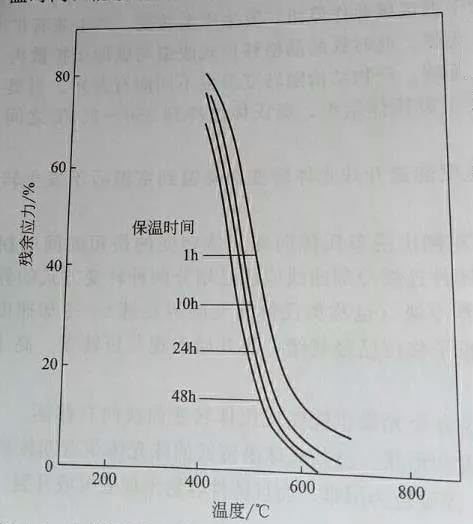

Stress relief in ductile iron castings is crucial for ensuring dimensional stability and preventing deformation. The process is influenced by heating temperature, holding time, and cooling rate.

· Temperature Range: Due to alloying elements, stress relief is typically performed at 580–600°C, staying below solid-state phase transition temperatures to preserve material properties.

· Cooling Process: Controlled slow cooling (e.g., 75°C/h to 350°C, then 100°C/h to 200°C) is essential to prevent new internal stresses.

· Initial Stress Matters: Castings with higher initial residual stress benefit more quickly from the stress relief process.

· Dual Treatment Strategy: For precision parts, a two-stage treatment is recommended:

1. Pre-machining – removes casting-induced stress.

2. Post-rough machining – removes stress introduced during machining and clamping.

This approach ensures high dimensional accuracy and structural integrity throughout the part’s service life.

-

Ductile iron castings, like other metal castings, naturally develop internal stresses during solidification due to uneven cooling and phase transformation. Additional stress is introduced during machining from cutting forces and clamping.If untreated, residual internal stress can release over time,Industry News

Ductile iron castings, like other metal castings, naturally develop internal stresses during solidification due to uneven cooling and phase transformation. Additional stress is introduced during machining from cutting forces and clamping.If untreated, residual internal stress can release over time,Industry News -

Ductile iron, widely developed in China over the past 40 years, is a strong, tough, and cost-effective casting material. Its spherical graphite structure reduces stress concentration, giving it better tensile strength, plasticity, and toughness than other cast irons. While its plasticity is lower thIndustry News

Ductile iron, widely developed in China over the past 40 years, is a strong, tough, and cost-effective casting material. Its spherical graphite structure reduces stress concentration, giving it better tensile strength, plasticity, and toughness than other cast irons. While its plasticity is lower thIndustry News -

At the foundry exhibition, Craftman presents it’s full range of casting riser cleaning solutions, offering visitors a modern cleaning experience that is efficient,safe and cost-effective. In the casting production process, the cleaning and separation of the pouring riser is a critical step that direCompany Exhibition

At the foundry exhibition, Craftman presents it’s full range of casting riser cleaning solutions, offering visitors a modern cleaning experience that is efficient,safe and cost-effective. In the casting production process, the cleaning and separation of the pouring riser is a critical step that direCompany Exhibition