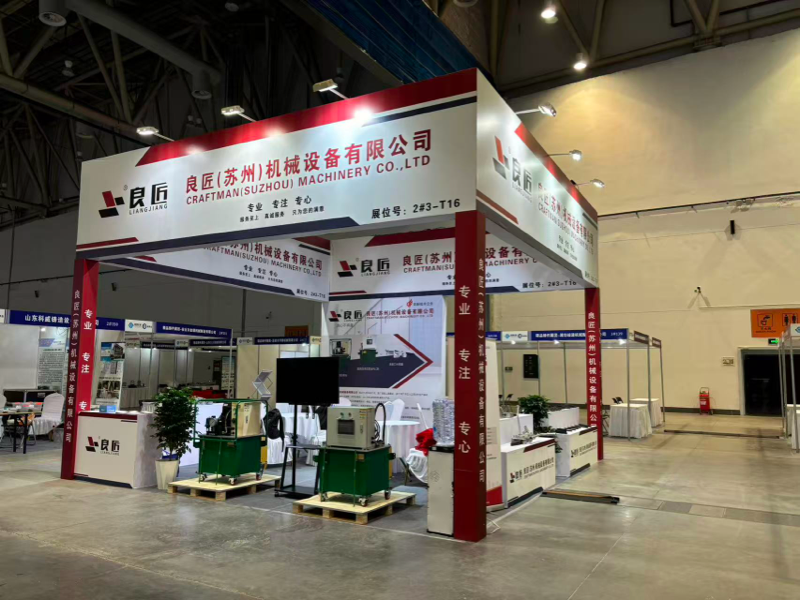

At the foundry exhibition, Craftman presents it’s full range of casting riser cleaning solutions, offering visitors a modern cleaning experience that is efficient,safe and cost-effective. In the casting production process, the cleaning and separation of the pouring riser is a critical step that directly impacts product quality, production costs, and workplace safety. Traditional methods such as manual hammering and grinding wheel cutting are not only labor-intensive and inefficient, but also pose significant risks, including potential damage to castings, high noise levels, dust pollution, and personal safety hazards.

Addressing these long-standing industry challenges, Craftman is dedicated to delivering a comprehensive suite of advanced equipment solutions that streamline riser removal, minimize risk, and improve overall operational efficiency.

Our Core Highlights At This Exhibition Include:

Casting sprue separator:

Achieve accurate and efficient batch separation

Significantly reduce the labor intensity of workers

Improve work efficiency

Ultra-high pressure hydraulic pump station:

Provides a stable hydraulic system for the complete set of hydraulic equipment. It has the characteristics of high pressure, stable flow, high reliability and long service life, and is the "power heart" of efficient cleaning.

Casting runner breaker:

It is exquisitely designed and easy to operate

Release the rapid and accurate breaking of runner for castings

Pneumatic impact hammer for casting riser:

Powered by compressed air

Large impact force

Suitable for cleaning medium and large castings and stubborn risers

An ideal choice to replace the impact of a large hammer.

“We are fully aware of the challenges and cost pressures faced in the casting cleaning process,” a Craftman representative stated. “At the Casting Exhibition, we’re not just showcasing a diverse range of products — our goal is to provide customers with comprehensive, one-stop solutions.”

From simple pneumatic tools to complex automated hydraulic systems, Craftman offers tailored equipment and customization services to meet the specific needs of each customer. Whether it's the material, geometry, or production rhythm of the castings, Craftman ensures the most suitable equipment selection to help customers maximize production efficiency and optimize overall operational costs.

-

Ductile iron castings, like other metal castings, naturally develop internal stresses during solidification due to uneven cooling and phase transformation. Additional stress is introduced during machining from cutting forces and clamping.If untreated, residual internal stress can release over time,Industry News

Ductile iron castings, like other metal castings, naturally develop internal stresses during solidification due to uneven cooling and phase transformation. Additional stress is introduced during machining from cutting forces and clamping.If untreated, residual internal stress can release over time,Industry News -

Ductile iron, widely developed in China over the past 40 years, is a strong, tough, and cost-effective casting material. Its spherical graphite structure reduces stress concentration, giving it better tensile strength, plasticity, and toughness than other cast irons. While its plasticity is lower thIndustry News

Ductile iron, widely developed in China over the past 40 years, is a strong, tough, and cost-effective casting material. Its spherical graphite structure reduces stress concentration, giving it better tensile strength, plasticity, and toughness than other cast irons. While its plasticity is lower thIndustry News -

At the foundry exhibition, Craftman presents it’s full range of casting riser cleaning solutions, offering visitors a modern cleaning experience that is efficient,safe and cost-effective. In the casting production process, the cleaning and separation of the pouring riser is a critical step that direCompany Exhibition

At the foundry exhibition, Craftman presents it’s full range of casting riser cleaning solutions, offering visitors a modern cleaning experience that is efficient,safe and cost-effective. In the casting production process, the cleaning and separation of the pouring riser is a critical step that direCompany Exhibition